Categories :

Unveiling the Core: Exploring the Various Honeycomb Panel Cores

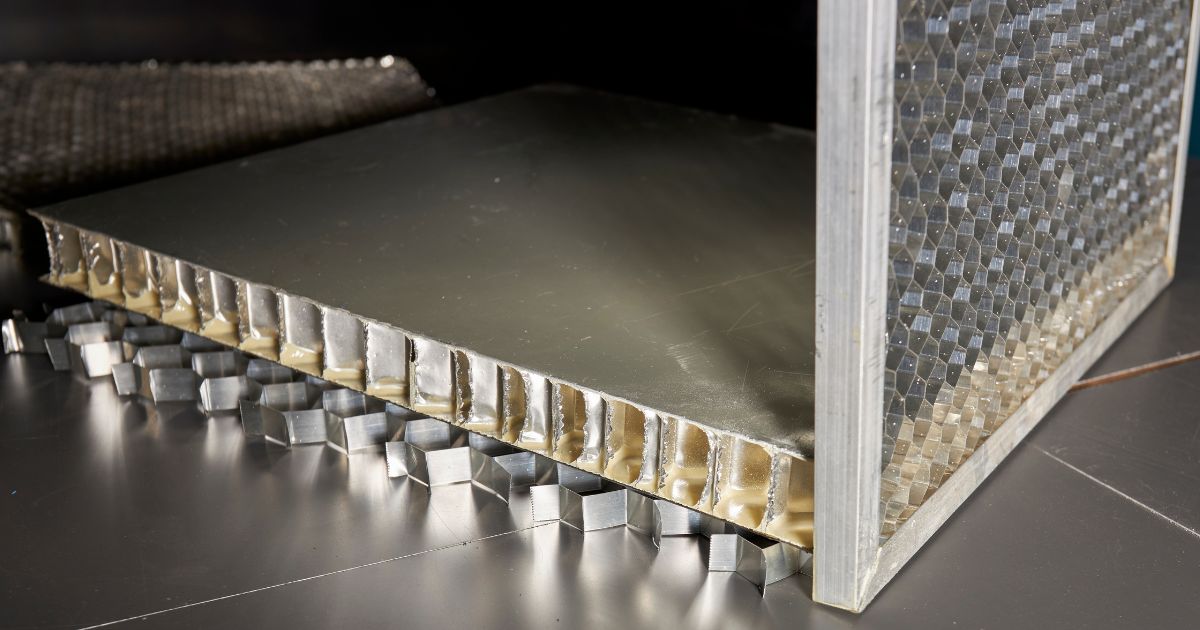

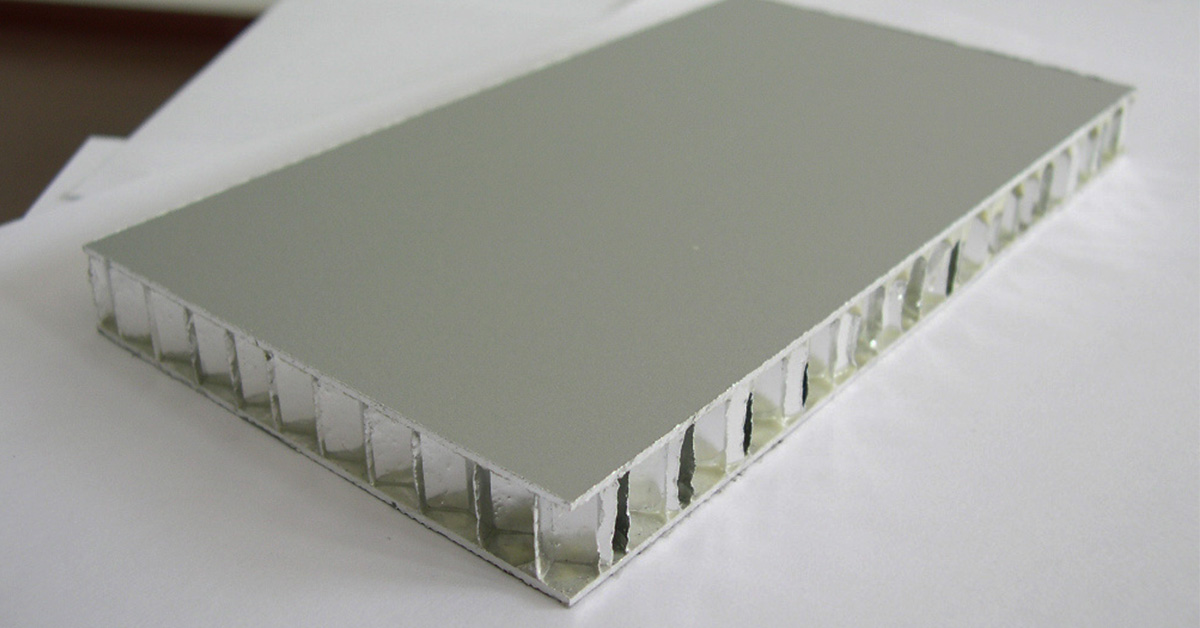

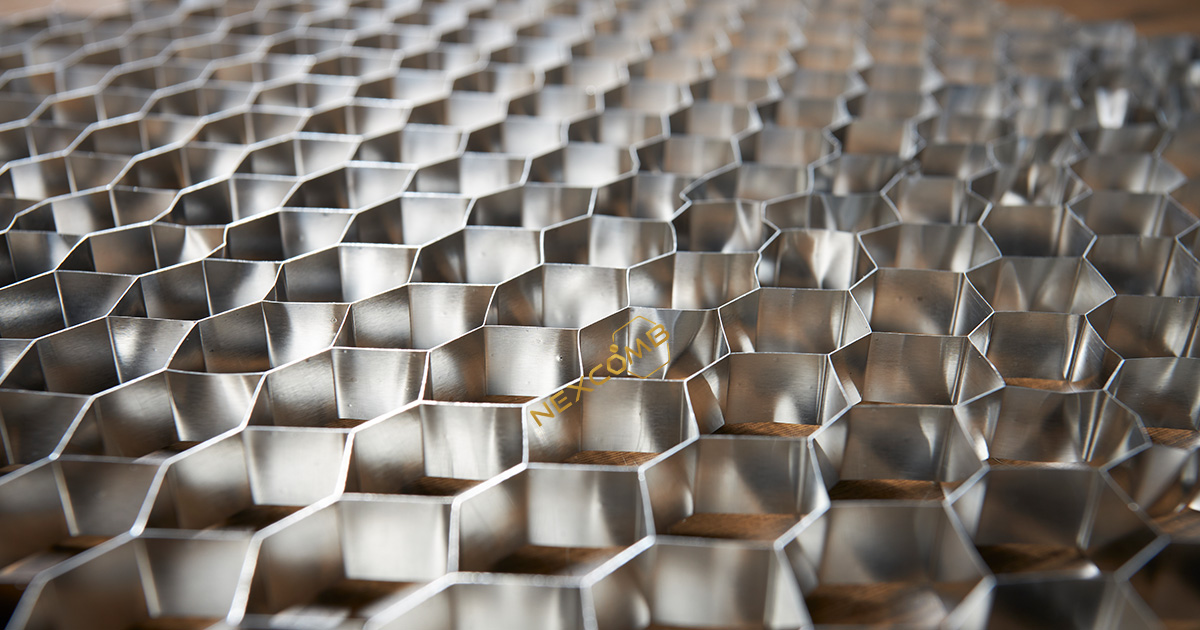

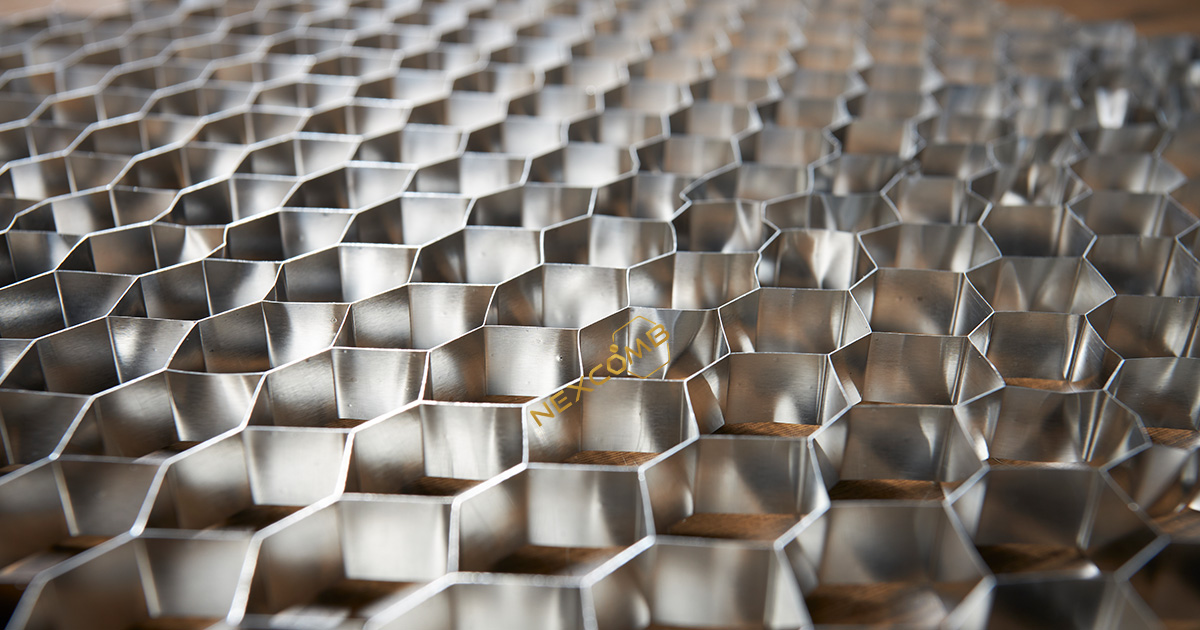

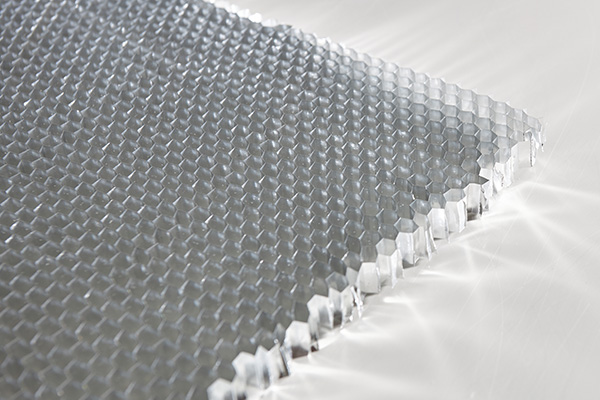

Honeycomb panels are revolutionizing the world of architecture and construction with their lightweight yet incredibly high compressive strength. The honeycomb panel cores are like the shapes of a hexagon which contributes to their mechanical performance and characteristics.

Importance of Core Materials in Honeycomb Panel Construction

The core material is the central component of honeycomb panels, providing structural support and stability while keeping the overall weight to a minimum. The choice of core material significantly influences the panel’s properties, including its strength, weight, and thermal insulation capabilities.

There are several types of Honeycomb Core Material, each offering unique benefits and characteristics. Some common core materials include:

- Aluminium: Aluminium honeycomb cores are known for their lightweight yet robust structure, making them ideal for applications requiring strength and durability.

- Nomex: Nomex cores are lightweight and fire-resistant, making them suitable for applications where fire safety is paramount, such as aerospace and industrial settings.

- Foam Cores: Foam cores, including polystyrene, PVC foam, polyurethane, and polypropylene, offer excellent insulation properties and are often used in applications requiring thermal and sound insulation.

- Thermoplastic: Thermoplastic cores are known for their versatility and recyclability, making them a sustainable choice for eco-friendly construction projects.

- Aerospace Cores: Aircraft honeycomb panels, tailored for aerospace needs, boast remarkable strength-to-weight ratios and are meticulously crafted to endure the most demanding conditions.

Structural Properties of Honeycomb Aluminium Panels

The structural properties of honeycomb aluminium panels are determined by the cell sizes of the core and the density. A smaller cell size and higher core density result in a stronger panel with improved impact resistance and a higher strength-to-weight ratio. This lightweight design makes honeycomb aluminium panels ideal for a wide range of applications, including aerospace, automotive, and architectural projects. With Nexcomb, the Nexcore (Aluminium Honeycomb Core) sizes vary across 6mm, 10mm, 14mm and 19mm. All of them are in the Alloy Grade AA3003 H-18.

Honeycomb Core Materials Overview

Honeycomb aluminium panels, as a type of composite panel, are inherently designed to be lightweight, fire-resistant, and sustainable – more so when they are from the house of Aludecor. Nexcomb’s composite nature ensures superior strength and durability while maintaining a reduced weight profile. Additionally, their fire-resistant properties offer enhanced safety, making them an ideal choice for various applications where both performance and sustainability are paramount. The application of Nexcomb and Nexcore is gaining traction for projects such as airports, clean rooms, elevators etc. Thus, the importance of fire retardant lightweight core materials is also being seen as an important one. And despite their initial cost, the long-term advantages of these panels outweigh the investment, delivering lasting value and peace of mind.

Read also: Why Should You Choose Aluminium Honeycomb Panels over Solid Aluminium Panels?

Advantages:

- Lightweight: Honeycomb panels are renowned for their lightweight properties, making them easy to transport, handle, and install.

- Fire-Resistant: Fire-resistant cores provide enhanced safety and are ideal for applications requiring compliance with strict fire regulations.

- Composite: Composite cores offer superior strength and durability, making them suitable for demanding structural applications.

- Sustainable: Sustainable core materials promote environmentally friendly construction practices and contribute to a greener future.

Application-Specific Honeycomb Panel Cores Selection

Choosing the right core material for a specific application is mandatory for optimizing performance and achieving desired outcomes.

For example, there are different types of honeycomb cores and you can get Nexcore of cell sizes 6mm, 10mm, 14mm and 19mm. by choosing the right Aluminium Honeycomb Core, it is possible to create lighter-weight automobile components. This can have a significant impact on reducing fuel consumption and energy usage. In aerospace and transportation applications, every ounce saved translates to increased efficiency and performance. With lighter components, vehicles require less energy to propel, leading to improved fuel economy and reduced emissions. This not only benefits the environment by lowering carbon footprint but also offers cost savings over the lifetime of the vehicle. Therefore, honeycomb aluminium panels are highly favoured in aerospace and transportation industries for their ability to optimize fuel efficiency and energy usage while maintaining structural integrity.

Read also: Application of Aluminium Honeycomb Panels in Aviation Industry

Did you know that Aludecor has its own production unit for core materials for honeycomb panels? Nexcore is invariably one of the new-age materials that can help the architects and façade consultants.

Fire-Resistant Cores

Fire-resistant cores, such as FR cores, are perfect for industrial applications where fire safety is paramount. These metal cores are designed to resist fire propagation, making them suitable for use in airports, laboratories, clean rooms, and other high-risk environments.

Sustainability Factor

The sustainability factor is increasingly important in modern construction projects. Renewable, recyclable core materials and eco-friendly manufacturing processes help minimize environmental impact and contribute to a more sustainable built environment. The choice of core materials plays a critical role in honeycomb panel performance and overall sustainability.

The selection of honeycomb panel cores is a critical aspect of honeycomb panel construction, influencing performance, durability, and sustainability. By understanding the various types of core materials available and their unique properties, architects, designers, and builders can make informed decisions to create structures that are both functional and environmentally responsible.

If you are interested in knowing more about the honeycomb aluminium panels and how Nexcomb is coming up as a trusted, new-age material in cladding, reach out 1800 102 0407 (toll-free). To know about the Nexcomb Aluminium Honeycomb Panel price, please send us an enquiry.