Importance of Aluminium Honeycomb Panels in Cleanrooms

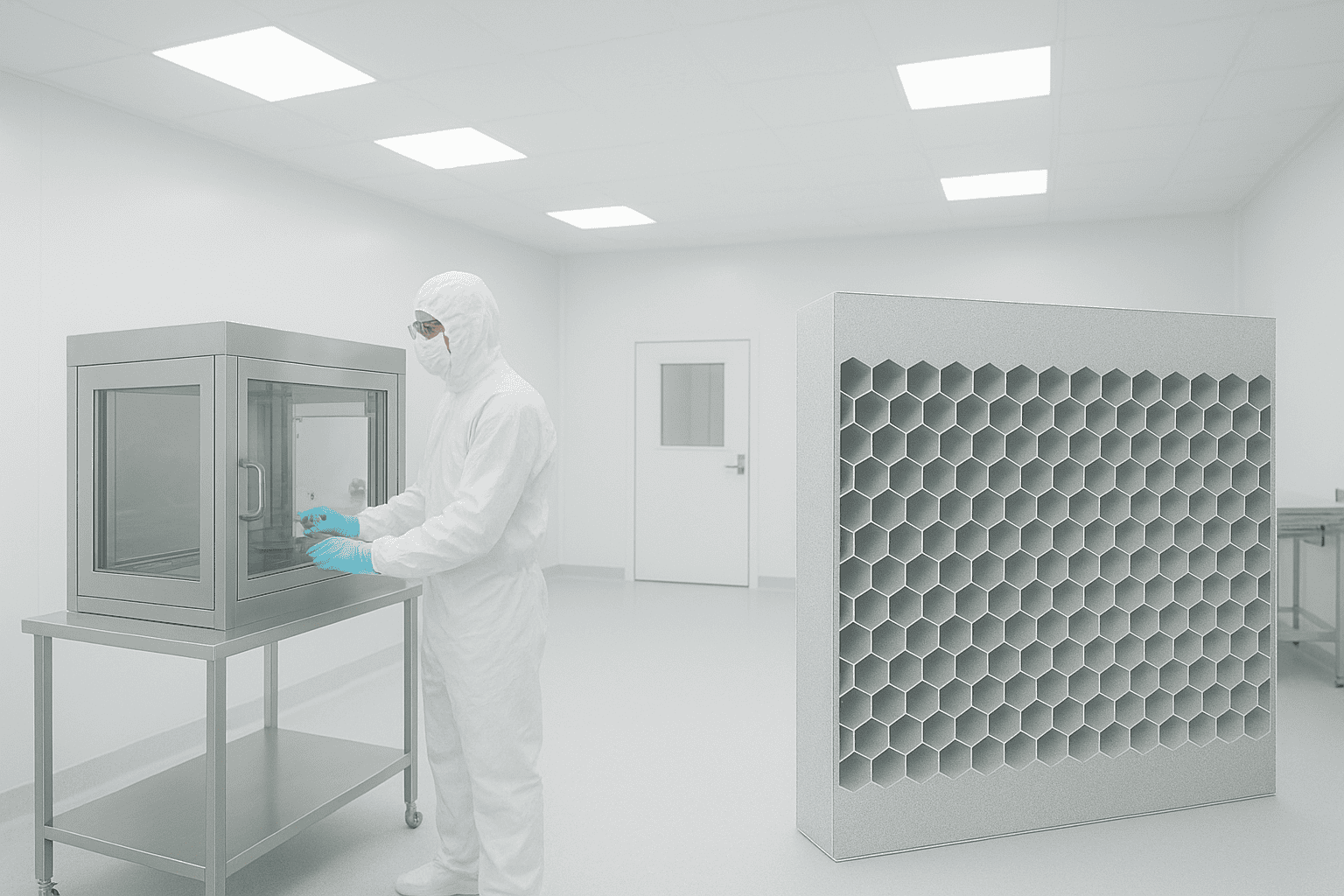

Cleanrooms are meticulously controlled environments essential for industries where even the smallest particle can compromise product integrity. In fields such as pharmaceuticals, electronics manufacturing, and biotechnology, the stakes are high. A single speck of dust can result in millions in losses. While traditional construction materials have been used, a superior solution has emerged: aluminium honeycomb panels.

These panels offer a range of properties that make them the optimal choice for constructing high-performance cleanroom facilities. Industry leaders like Aludecor, through their Nexcomb series, have refined this technology to meet the stringent requirements of cleanroom applications.

Understanding Aluminium Honeycomb Panels

Aluminium honeycomb panels are sandwich-structured composites made of two thin aluminium sheets bonded to a core of expanded aluminium foil. The hexagonal design of the core, inspired by natural honeycombs, distributes loads evenly and offers exceptional rigidity while keeping the panels lightweight.

- Lightweight: They are significantly lighter than solid panels, easing transportation and installation.

- Rigidity: The honeycomb core provides excellent structural stability, preventing deformation.

- Fire resistance: Aluminium is non-combustible, contributing to fire safety.

- Corrosion resistance: Aluminium naturally resists corrosion, ensuring longevity in sterile environments.

These features make aluminium honeycomb panels an excellent fit for cleanrooms, where durability and contamination control are priorities.

Also Read: Aluminium Honeycomb Panels The Future of Lightweight, High-Strength Solutions

Advantages of Aluminium Honeycomb Panels in Cleanrooms

Contamination Control- The smooth, non-porous surfaces of aluminium honeycomb panels minimize the accumulation of dust and microbes, facilitating easy cleaning and sterilization processes. This is crucial in cleanrooms where maintaining particle-free environments is mandatory.

Structural Benefits- Their high strength-to-weight ratio allows for robust construction of partitions, walls, ceilings, and doors without adding excessive weight or risking deformation. This flexibility supports modular designs and enhances facility adaptability.

Thermal and Acoustic Performance- The honeycomb core provides excellent thermal insulation that helps maintain steady temperatures inside the cleanroom, reducing energy consumption. Additionally, it offers sound dampening qualities that contribute to a quieter workspace.

Fire Safety: As aluminium honeycomb panel manufacturers in India and globally adhere to strict safety standards. Their inherent non-combustibility makes them a vital choice for safe cleanroom construction.

A Leading Example: Aludecor’s Nexcomb Series

When considering aluminium honeycomb panel manufacturers in India, the Nexcomb series from Aludecor stands out as a prime example of a high-quality, indigenously developed product. The series is powered by “Nexcore,” an in-house aluminium honeycomb core, making Aludecor the first company in the country to produce its core material. This allows for superior quality control and customization.

The panels are explicitly designed for applications like cleanrooms and partitions, offering:

- Aludecor’s Nexcomb panels offer a high fire-performance rating (Class A2) for enhanced safety.

- Thanks to their indigenous “Nexcore,” the panels provide an exceptional strength-to-weight ratio for easy handling and structural integrity.

- The series features a premium, corrosion-resistant finish, ensuring durability and aesthetic appeal.

This series demonstrates that Indian manufacturers are at the forefront of providing advanced, reliable aluminium honeycomb panels that meet international standards.

Also Read: Aluminium Honeycomb Panels From Aludecor Powered By In-house Honeycomb Core Manufacturing

Comparison with Alternative Materials

When compared to a common alternative, such as solid aluminium panels, the honeycomb structure offers a clear advantage. While both are corrosion-resistant and durable, the aluminium honeycomb structure provides superior rigidity and strength at a fraction of the weight. Solid panels are heavier and more prone to warping or bending under stress, making the honeycomb variant a more stable and cost-effective choice for large-scale construction. Aluminium honeycomb panels outperform many traditional materials making them a preferred choice for modern facilities.

| Feature | Aluminium Honeycomb Panels | Alternative Modular Panels (e.g., PU/PIR) | Traditional Construction (e.g., Drywall/Brick) |

| Contamination Control | Non-shedding, smooth, sealed surface. Minimal particle shedding, easy to clean and sterilize. | Can shed particles if damaged. Porous cores may harbor microbes. Surfaces are easy to clean. | Flakes or crumbles if damaged. Porous materials can trap particles and microbes. |

| Weight & Rigidity | Extremely lightweight with a high strength-to-weight ratio. High rigidity prevents deformation. | Lightweight but generally less rigid than honeycomb. Rigidity depends on core density. | Very heavy. Requires significant structural support. Not portable. |

| Fire Safety | Non-combustible aluminium core with a high fire-performance rating (e.g., Class A2). | Fire resistance varies. PU/PIR cores are often fire-retardant but can still be flammable or release toxic smoke. | Fire resistance varies, often requiring additional fireproofing layers. |

| Modularity & Installation | Modular and prefabricated, allowing for very fast assembly and disassembly. Easy to reconfigure and expand. | Also modular and prefabricated, with quick installation. Can be reconfigured. | Permanent installation. Time-consuming construction. Difficult to reconfigure or move. |

| Longevity & Maintenance | Corrosion-resistant, highly durable. Easy to clean and sanitize, with minimal long-term maintenance required. | Prone to dents or damage. Surface finishes may degrade. Can be difficult to repair without replacement. | Durable but can be susceptible to moisture damage. Repair is often messy and disruptive. |

| Cost | Higher initial cost but lower long-term costs due to reduced labor, faster installation, and durability. | Generally more cost-effective upfront than honeycomb, but less durable over time. | Lower initial material cost but higher labor costs and longer project timelines. |

Maintenance and Longevity

Aluminium honeycomb panels are highly durable and resistant to corrosion and wear, making them suitable for the demanding conditions of cleanroom environments. Their smooth surface allows for straightforward cleaning routines, essential for maintaining hygiene standards. Although the upfront cost may be higher than conventional materials, their longevity and reduced maintenance make them a cost-effective option over time.

Manufacturers like Aludecor, with their Nexcomb series tailored for the Indian market, provide reliable aluminium honeycomb panels meeting stringent specifications for cleanrooms.

Applications of Aluminium Honeycomb Panels in Cleanroom Environments

These panels find applications across various cleanroom components such as:

- Enclosures for equipment, minimizing contamination risks around sensitive machinery.

- Partitions and walls that can be reconfigured for changing operational needs.

- Ceilings and raised flooring systems designed for lightweight durability.

- Cleanroom doors that require strength while remaining lightweight and easy to operate.

Conclusion

In the demanding world of controlled environments, the choice of construction material is paramount. Aluminium honeycomb panels stand out as the definitive solution for cleanrooms, providing an unparalleled combination of contamination control, structural integrity, and safety. From their unique aluminium honeycomb structure to their practical advantages in maintenance and longevity, these panels are an essential component for any cleanroom designer or builder. For those seeking enhanced performance and sustainability, considering aluminium honeycomb panels India or other local aluminium honeycomb manufacturers in India is a strategic decision for the integrity and success of their cleanroom operations.

Why choose Nexcomb as your aluminium honeycomb panel manufacturer in India for cleanrooms?

Nexcomb stands out as a top aluminium honeycomb panel manufacturer in India because of its fully automated, in-house aluminium honeycomb core manufacturing facility. This ensures strict quality control, consistent honeycomb core density, and superior bonding strength. For cleanroom projects requiring tested honeycomb composite panels, Nexcomb offers certified performance, customization flexibility, and reliable supply as a trusted aluminium honeycomb panel supplier.

How do Nexcomb honeycomb panels compare to traditional cleanroom wall systems?

Unlike drywall, brick, or PU-based systems, Nexcomb honeycomb sandwich panels offer an unmatched strength-to-weight ratio. The honeycomb structural panels maintain flatness and rigidity without adding excessive dead load. Being lightweight honeycomb panels, they allow faster modular installation and easy reconfiguration. While the aluminium honeycomb panel price may be higher initially, long-term durability and reduced maintenance make Nexcomb a cost-efficient solution.

Are Nexcomb aluminium honeycomb panels fire-safe for pharmaceutical cleanrooms?

Yes. Nexcomb aluminium honeycomb sandwich panels meet EN 13501-1 Class A2-s1,d0 fire performance standards. This means the honeycomb core material is non-combustible, produces negligible smoke, and does not contribute to flame spread. Compared to conventional modular panels, Nexcomb honeycomb composite panels provide enhanced fire resistance, making them suitable for high-risk cleanroom facilities where compliance and safety are non-negotiable.

How does Nexcomb ensure superior contamination control in cleanroom applications?

Nexcomb alu honeycomb panels feature factory-finished aluminium honeycomb sheet surfaces that are non-porous, easy to sanitize, and resistant to corrosion. The closed aluminium honeycomb core prevents moisture absorption and microbial growth, unlike porous alternatives. As a trusted aluminium honeycomb panel manufacturer in India, Nexcomb panels are designed to meet stringent cleanroom standards, ensuring hygienic, long-term performance in controlled environments.

Why are Nexcomb aluminium honeycomb panels ideal for cleanroom construction?

Nexcomb aluminium honeycomb panels are engineered specifically for high-performance environments like cleanrooms where contamination control and structural stability are critical. Powered by an in-house aluminium honeycomb core, Nexcomb panels offer a smooth, sealed honeycomb sheet surface that minimizes particle shedding and microbial buildup. Their lightweight honeycomb panels reduce structural load while delivering exceptional rigidity, making them a preferred honeycomb building material for pharmaceutical and electronics cleanrooms.